The European standard double girder bridge crane is a high-performance lifting equipment based on European lightweight and modular design principles. It integrates international standards (such as FEM, DIN, and ISO) with advanced manufacturing technologies, making it widely applicable for material handling in industrial settings. Its core design objective is to reduce deadweight and wheel load through structural optimization, thereby minimizing the structural load requirements on the building while enhancing operational efficiency and safety. This type of crane typically consists of a bridge frame, main girders, hoisting mechanisms, and electrical systems, featuring a compact design and highly intelligent control systems.

Features of European Standard Double Girder Bridge Cranes

Compact Structure & Lightweight Design:

The European standard double girder bridge crane adopts optimized design, resulting in a deadweight much lighter than traditional cranes. This achieves low headroom and low wheel load, effectively utilizing workshop space and reducing civil engineering costs.

Smooth Operation & Precise Positioning:

Frequency control speed regulation and "three-in-one" drive technology are widely used. It enables smooth starting and stopping, achieving precise positioning to meet high-accuracy operational requirements.

High Safety & Reliability:

The European standard double girder bridge crane is equipped with comprehensive safety devices like dual braking systems and multiple limit protections. Key components comply with strict European standards, ensuring long-term operational reliability.

Energy Efficiency & Easy Maintenance:

Due to its lightweight design and highly efficient drive, energy consumption is significantly reduced. Modular design facilitates daily inspections, maintenance, and component replacement.

Applications of European Standard Double Girder Bridge Cranes

Workshops with Space Constraints: Particularly suitable for new or renovated workshops with strict headroom requirements.

Precision Manufacturing Sectors: Widely used in industries requiring precise hoisting, such as automotive, precision instruments, and electronic products.

High-Intensity Working Environments: Applicable for frequent and heavy-load operations in logistics, metallurgy, chemical industry, etc.

Locations with Special Environmental Requirements: Can be customized to serve special industrial environments like clean rooms, explosion-proof, or high-temperature settings.

-

Main Girder The core load-bearing structure of the bridge, supporting all loads and transferring them to the end beams. Lightweight design is adopted to reduce the load on the plant.

Main Girder The core load-bearing structure of the bridge, supporting all loads and transferring them to the end beams. Lightweight design is adopted to reduce the load on the plant. -

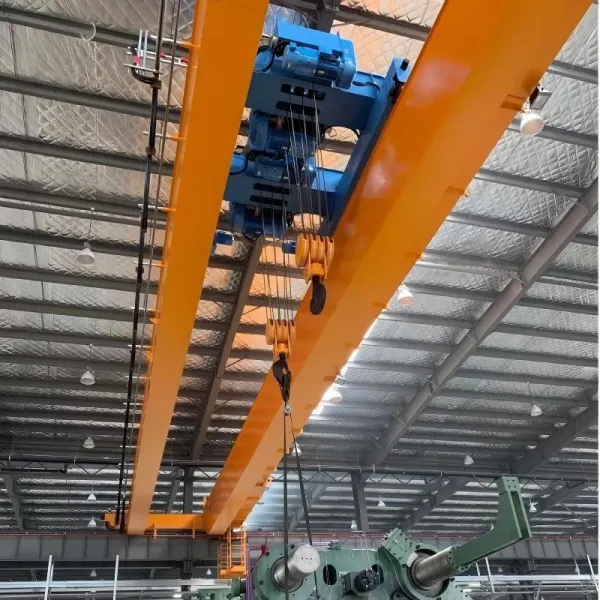

Crane Trolley The core system for lifting loads, including motors, reducers, drums, brakes and wire ropes. Supports variable frequency speed regulation, stable operation, and is equipped with a two-stage height limiter to ensure safety.

Crane Trolley The core system for lifting loads, including motors, reducers, drums, brakes and wire ropes. Supports variable frequency speed regulation, stable operation, and is equipped with a two-stage height limiter to ensure safety. -

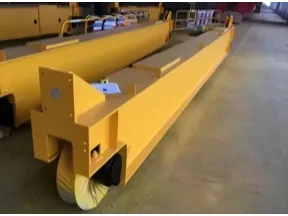

End Girder: Integrating the trolley wheels and drive device. Drive the whole machine to move longitudinally along the plant track, with a universal wheel design to prevent rail gnawing.

End Girder: Integrating the trolley wheels and drive device. Drive the whole machine to move longitudinally along the plant track, with a universal wheel design to prevent rail gnawing. -

Wheels Forged steel with double rims to prevent derailment.

Wheels Forged steel with double rims to prevent derailment.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling