The self-propelled scissor lift (also known as a self-propelled scissor aerial work platform) is an intelligent piece of engineering machinery that integrates electric drive, self-propelled movement, and hydraulic lifting functions. It is driven by hydraulic or electric power, capable of safely and flexibly elevating personnel and tools to specified working heights. The Self-propelled scissor lift can walk freely in the lifting state, thus improving the efficiency and continuity of work.

The most significant distinctions between it and traditional fixed lifts or equipment requiring external traction are its "self-propelled" capability and "integrated" design.

Features of the self-propelled scissor lift:

Compared to conventional equipment, self-propelled scissor lifts offer significant advantages in efficiency, safety, and environmental friendliness.

1. High Efficiency

Self-Propelled Functionality (In-Motion Elevation): Operators can control the platform to move slowly and steadily at height without needing to lower it for repositioning.

Ease of Operation: The equipment is typically fitted with a platform-mounted control panel and a remote control for the chassis, making operation intuitive and easy to learn.

Rapid Response and Deployment: The compact design and high mobility allow the equipment to be quickly transferred from one work point to another.

2. Safety

Active Safety Systems:

Tilt Protection System: Built-in tilt sensors automatically trigger audible and visual alarms and lock all functions except descent if the chassis tilts beyond a safe angle (typically 3-5 degrees), effectively preventing tip-over accidents.

Passive and Emergency Safety Systems:

Emergency Descent Device: Allows the platform to be safely lowered to the ground via a manual pump or gravity descent valve in case of power failure or main hydraulic system malfunction.

Emergency Stop Buttons: Located on both the platform and the chassis, these buttons instantly cut power in an emergency.

Anti-Pinch Design: Protective blocks or sensors are installed at scissor arm intersections to prevent crushing injuries.

Platform Overload Alarm: The system alarms and restricts movement if the load exceeds the rated capacity.

Structural Safety:

The scissor lift mechanism itself offers high stability and load-bearing capacity, ensuring smooth lifting and lowering without the risk of sudden, uncontrolled descent.

The work platform is equipped with full perimeter guardrails and a lockable safety gate to prevent accidental falls.

3. Adaptability and Environmental Friendliness

Compact Design: Enables access to confined indoor spaces.

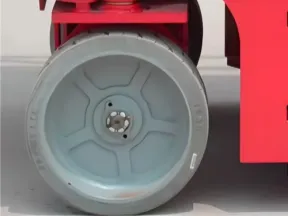

Diverse Tire Options:

Polyurethane Solid Wheels: Ideal for smooth indoor floors, leaving no marks and protecting the surface.

Non-Marking Tires: Made from special rubber compounds, offering elasticity without damaging floors.

Pneumatic/All-Terrain Tires: Suitable for rough outdoor surfaces, providing good shock absorption and traction.

Zero Emissions, Low Noise: Battery-powered operation results in no exhaust emissions and minimal noise, making them highly suitable for environmentally sensitive indoor venues like shopping malls, hospitals, and office buildings.

Low Maintenance Costs: The electro-hydraulic system is relatively simple, leading to lower failure rates and easier routine maintenance compared to internal combustion engine equipment.

Application of the self-propelled scissor lift:

1.Warehousing and Logistics: Accessing and organizing high-level racking; installation and maintenance of lighting, monitoring, and fire safety equipment on warehouse ceilings; internal pipeline maintenance. A core piece of equipment in modern smart warehouses.

2.Building Construction and Factory Maintenance: Interior finishing (ceiling, wall, and light installation); plant maintenance (equipment installation/repair, pipeline work, steel structure maintenance); internal work during the mid-to-late stages of building construction.

3.Commercial and Public Facilities: Routine cleaning, light replacement, decorative installation, and signage mounting in shopping centers, airports, stadiums, and convention centers. Their quiet, clean operation is crucial for these environments.

4.Industrial Production: Providing flexible, mobile elevated work platforms for assembly lines in automotive manufacturing, aircraft repair, and large equipment assembly.

5.Specialized Industries: Power facility maintenance (substation equipment); shipbuilding and repair; landscaping (tree trimming); film and television production (lighting and camera positioning).

-

Wheels: Types include polyurethane solid (indoor, floor-protective), non-marking (elastic, trace-free), pneumatic/all-terrain (outdoor rough ground, shock-absorbent). Motor-driven drive wheels + swivel casters (steering) for flexible mobility.

Wheels: Types include polyurethane solid (indoor, floor-protective), non-marking (elastic, trace-free), pneumatic/all-terrain (outdoor rough ground, shock-absorbent). Motor-driven drive wheels + swivel casters (steering) for flexible mobility. -

Battery: Lead-acid (cost-effective, durable) or lithium-ion (lighter, fast-charging, long-life, no memory effect). Regular charging required; periodic maintenance charging needed during prolonged storage.

Battery: Lead-acid (cost-effective, durable) or lithium-ion (lighter, fast-charging, long-life, no memory effect). Regular charging required; periodic maintenance charging needed during prolonged storage. -

Scissor Mechanism: High-strength steel arms connected by pins (scissor design), extended/retracted via hydraulic cylinder. Stable structure, strong load-bearing, smooth & reliable lifting/lowering.

Scissor Mechanism: High-strength steel arms connected by pins (scissor design), extended/retracted via hydraulic cylinder. Stable structure, strong load-bearing, smooth & reliable lifting/lowering. -

Ground Working Platform: Integrates drive system (motors, drive/steerable wheels), hydraulic power system (pump station, oil tank, motor), and control/electrical system (battery, main controller, tilt sensors) on interior/underside.

Ground Working Platform: Integrates drive system (motors, drive/steerable wheels), hydraulic power system (pump station, oil tank, motor), and control/electrical system (battery, main controller, tilt sensors) on interior/underside.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling