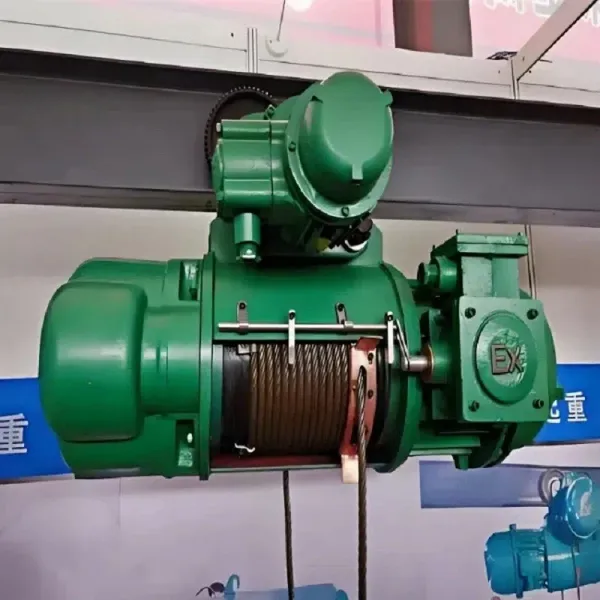

HB Type Explosion Proof Electric Hoist is used in areas with combustive and other explosive dust. This type of crane has features of small weight and bigger lift capacity and better structure.

HB Type Explosion Proof Electric Hoist, with explosion-proof grades of DIBT4 and DICT4 respectively. The main body of HB type wire rope explosion-proof electric hoist can be suspended on the I-beam track for straight or curved operation, or installed on a fixed bracket for lifting heavy objects.

Features of HB Type Explosion Proof Electric Hoists

1. Explosion-Proof Treatment of Key Components:

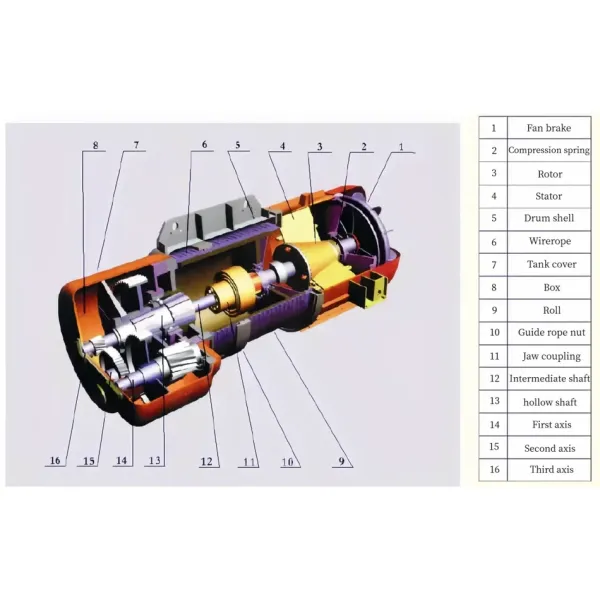

Explosion-Proof Motor: Utilizes flame-proof motors. Their housing possesses extremely high strength, capable of containing any internal explosion (e.g., from an electrical spark due to winding short-circuit). It isolates the flame and high-temperature gases within the housing, allowing them to cool sufficiently while passing through housing gaps, thereby preventing ignition of the external explosive atmosphere.

Explosion-Proof Control Electrical Apparatus: Includes explosion-proof push-button switches, limit switches, contactors, and ultimate limit switches. The contacts of these components are enclosed within flame-proof housings, effectively sealing operational sparks.

Explosion-Proof Junction Box: All cable entries and connections are made through dedicated explosion-proof junction boxes to prevent electrical sparks from escaping at connection points.

2. Spark-Resistant Design for Mechanical Parts:

Explosion-Proof Brake: The brake can generate friction sparks during operation. Therefore, its manufacturing materials (such as beryllium bronze, aluminum bronze, and other spark-resistant metals) and structure are specially designed.

Anti-Collision Measures: The hoist's travel trolley and lifting mechanism are usually equipped with anti-collision buffers to prevent severe impacts between metal parts that could generate mechanical sparks.

Grounding Protection: A comprehensive grounding system prevents the accumulation of static electricity and subsequent spark generation.

3. Housing Material:

Extensive use of spark-resistant materials, such as copper alloys (H62 brass, beryllium bronze), stainless steel, or high-strength engineering plastics. These materials are less likely to generate mechanical sparks when colliding with each other or with ferrous metals.

Applications of HB Type Explosion Proof Electric Hoists

Explosion-proof electric hoists are specifically designed for use in potentially explosive environments. Their main application fields include:

1. Petroleum, Chemical, and Natural Gas Industries:

Scenarios: Refineries, chemical plants, fertilizer plants, natural gas processing stations, gas station maintenance workshops.

Hazardous Substances: Flammable gases or vapors volatilized from crude oil, gasoline, diesel, natural gas, ethylene, propylene, benzene compounds, etc.

2. Coal Industry:

Scenarios: Underground coal mines (especially gas-prone mines).

Hazardous Substances: Methane (firedamp), coal dust.

3. Paint, Coating, and Spraying Industries:

Scenarios: Spray booths, paint manufacturing workshops, coating lines.

Hazardous Substances: Flammable solvent vapors volatilized from paints, thinners, lacquer thinners, etc.

4. Grain, Oil Processing, and Feed Industries:

Scenarios: Flour mills, sugar refineries, edible oil processing plants, feed processing workshops.

Hazardous Substances: Combustible dusts suspended in the air, such as flour, starch, sugar, feed dust.

5. Military and Aerospace Industries:

Scenarios: Propellant and ammunition manufacturing workshops, rocket fuel loading areas, aircraft hangars (involving fuel).

Hazardous Substances: Gunpowder dust, propellant vapors, aviation fuel vapors.

6. Other Locations with Combustible Dusts:

Scenarios: Metal processing (aluminum, magnesium powder), woodworking (sawdust), plastic pelletizing, etc.

Hazardous Substances: Corresponding combustible dusts.

-

Electrical Box: Houses core hoist control components (contactors, relays, etc.). Flameproof joints; explosion-proof cable glands. Low-arcing internals; marked safety grounding terminal.

Electrical Box: Houses core hoist control components (contactors, relays, etc.). Flameproof joints; explosion-proof cable glands. Low-arcing internals; marked safety grounding terminal. -

Travel Trolley: Carries electric hoist, moves left/right along I-beam track. Flameproof motor; spark-resistant wheels (copper alloys/high-strength nylon). Anti-collision buffers (polyurethane) absorb impact, avoiding spark-causing metal contact.

Travel Trolley: Carries electric hoist, moves left/right along I-beam track. Flameproof motor; spark-resistant wheels (copper alloys/high-strength nylon). Anti-collision buffers (polyurethane) absorb impact, avoiding spark-causing metal contact. -

Explosion-Proof Pendant: High-strength plastic/spark-resistant metal (e.g., copper alloy) housing with flameproof strength & joints. Sealed buttons/micro-switches; spark-proof. Explosion-proof cable gland for isolation.

Explosion-Proof Pendant: High-strength plastic/spark-resistant metal (e.g., copper alloy) housing with flameproof strength & joints. Sealed buttons/micro-switches; spark-proof. Explosion-proof cable gland for isolation. -

Explosion-Proof Motor: Powers hoist lifting/traveling. High-strength cast iron/steel housing resists internal explosion pressure. Heat dissipation controls surface temp; high IP rating (dust/waterproof) suits harsh industrial environments.

Explosion-Proof Motor: Powers hoist lifting/traveling. High-strength cast iron/steel housing resists internal explosion pressure. Heat dissipation controls surface temp; high IP rating (dust/waterproof) suits harsh industrial environments.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling