The HD Type European Standard Single Girder Bridge Crane represents the future development direction of industrial lifting equipment characterized by lightweight design, intelligent control, and high reliability.

It is not merely a simple handling tool but an integrated, high-efficiency material handling solution that combines advanced mechanical design, intelligent electronic control systems, and stringent safety management.

Choosing it means opting for higher production efficiency, extended equipment service life, lower total cost of ownership, and inherent safety assurance.

Characteristics of HD Type European Standard Single Girder Bridge Cranes

The features of HD Type European standard single girder overhead cranes are mainly reflected in the following aspects:

1. Scientific and Rigorous Design

Fatigue Strength-Based Design: The steel structure and mechanical systems are designed not only to meet maximum static load requirements but also by calculating stress cycle counts over the entire design service life, ensuring durability under frequent and high-intensity operations.

Modular Design: Standardized modular drive units (highly integrating motors, brakes, and gearboxes) are adopted, offering compact structure, high transmission efficiency, and ease of maintenance and replacement.

Clear Duty Classification: Internationally recognized FEM duty classes (e.g., A3, A4, A5) are used to precisely specify the crane's working capability, scientifically matching the actual usage frequency and load conditions of users.

2. Exceptional Performance

Smooth Operation and Precise Positioning: Frequency conversion stepless speed regulation technology (standard feature) is widely used, enabling soft starting and stopping of loads, significantly reducing operational impact and load sway, and facilitating precise positioning and assembly tasks.

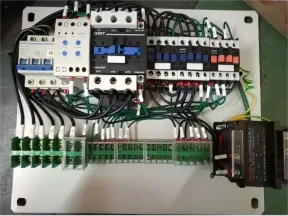

Intelligent Control: With a PLC (Programmable Logic Controller) at the core, the system includes functions such as fault self-diagnosis, real-time monitoring (e.g., load weight, motor status), and data recording, offering high intelligence and ease of maintenance.

3. High Safety and Reliability

Redundant Safety Protection: Multiple safety devices are equipped, such as a dual braking system (service brake + safety brake), dual limit switches (operational limit + emergency limit), and overload limiters (automatically cutting off unsafe operations), constructing a comprehensive safety protection system.

High-Quality Core Components: Key parts (e.g., motors, brakes, electrical control systems, electrical components) generally use internationally renowned brands, ensuring reliability and long service life from the source.

4. Compact Structure and Lightweight Design

"Three Small" Features: Small end carriage dimensions, small wheelbase, and low overall height. This design maximizes the vertical space utilization of the workshop, provides greater effective lifting height, and reduces the wheel load on the workshop runway beams, potentially lowering civil engineering costs.

Excellent Anti-Corrosion Performance: The steel structure undergoes strict shot blasting and rust removal treatment, with multi-layer spraying of high-quality epoxy zinc-rich primer and polyurethane topcoat, offering strong corrosion resistance suitable for various harsh industrial environments.

5. Low Maintenance Costs

Thanks to its scientific design, high-quality components, and modular structure, the failure rate is extremely low.

Many components feature maintenance-free or low-maintenance designs (e.g., sealed bearings, disc brakes), significantly reducing daily maintenance workload and long-term operational costs.

Applications of HD Type European Standard Single Girder Bridge Cranes

Due to the above outstanding characteristics,HD Type European standard single girder overhead cranes are widely used in modern industrial fields with high requirements for efficiency, safety, and reliability, including but not limited to:

1.Smart Manufacturing and Precision Assembly Workshops: Used for handling and assembling precision parts, where smooth operation and precise positioning are critical.

2.Busy Warehousing and Logistics Centers: Suitable for high-frequency, fast-paced material handling and loading/unloading operations, with high duty class and reliability ensuring continuous operation capability.

3.Automobile Manufacturing and Parts Industry: Used for handling heavy objects such as bodies, molds, and engines on production lines, requiring efficient, safe, and fault-free equipment.

4.Aerospace Sector: Used for handling expensive precision instruments and aircraft components, where safety and stability requirements are extremely stringent.

5.Food and Pharmaceutical Industries: Can be made of stainless steel or specially treated for corrosion resistance, meeting the specific requirements of clean rooms and corrosive environments.

6.Paper and Chemical Industries: Capable of adapting to harsh working conditions such as high temperature, high humidity, or the presence of corrosive gases.

-

Main GirderMade of high-strength steel, eccentric rail box-girder design with runway rail offset from central axis. Delivers excellent horizontal stiffness and torsional resistance, reducing structural weight without compromising load-bearing capacity.

Main GirderMade of high-strength steel, eccentric rail box-girder design with runway rail offset from central axis. Delivers excellent horizontal stiffness and torsional resistance, reducing structural weight without compromising load-bearing capacity. -

Electric Hoist A modular hoisting unit equipped with frequency control for smooth and precise lifting operation. Designed for underslung mounting along the lower flange of the main girder, it ensures easy access and efficient maintenance.

Electric Hoist A modular hoisting unit equipped with frequency control for smooth and precise lifting operation. Designed for underslung mounting along the lower flange of the main girder, it ensures easy access and efficient maintenance. -

End Girder Incorporates an integrated "three-in-one" drive unit (motor, brake, and reducer). Its compact wheelbase and low profile improve workspace utilization and minimize wheel load on the runway structure.

End Girder Incorporates an integrated "three-in-one" drive unit (motor, brake, and reducer). Its compact wheelbase and low profile improve workspace utilization and minimize wheel load on the runway structure. -

Lifting Hook Forged from high-strength alloy steel and rigorously tested with heat treatment and nondestructive inspection. The trapezoidal cross-section prevents sling slippage and enhances operational safety.

Lifting Hook Forged from high-strength alloy steel and rigorously tested with heat treatment and nondestructive inspection. The trapezoidal cross-section prevents sling slippage and enhances operational safety. -

Wireless Remote Control Allows the operator to control the crane from the floor with improved visibility and safety. It employs secure anti-interference communication protocols and includes an emergency stop button for instant response.

Wireless Remote Control Allows the operator to control the crane from the floor with improved visibility and safety. It employs secure anti-interference communication protocols and includes an emergency stop button for instant response. -

Control Panel Functions as the control center of the crane, using a PLC for fault diagnostics and real-time monitoring. Rated up to IP55, it provides reliable protection against dust and moisture.

Control Panel Functions as the control center of the crane, using a PLC for fault diagnostics and real-time monitoring. Rated up to IP55, it provides reliable protection against dust and moisture. -

Wheels Made from quenched alloy forged steel for high wear resistance and fatigue strength. Horizontal guide wheels are fitted to the end carriages to prevent lateral rail grinding during travel.

Wheels Made from quenched alloy forged steel for high wear resistance and fatigue strength. Horizontal guide wheels are fitted to the end carriages to prevent lateral rail grinding during travel.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling