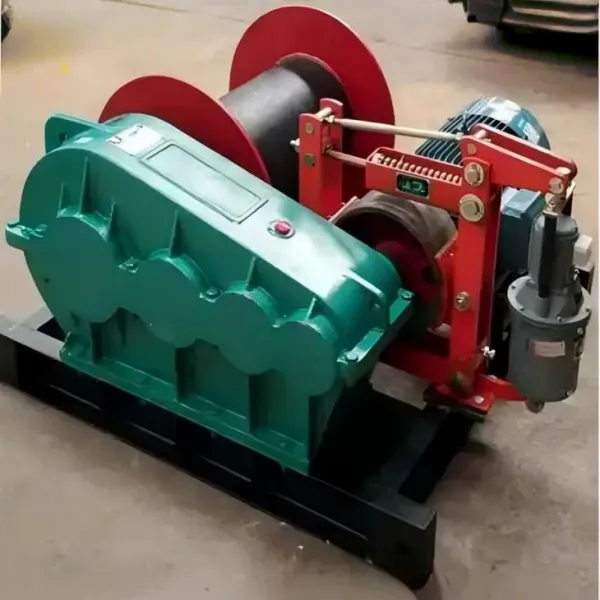

The JM type electric winch, fully named Electrically Controlled Slow-Speed Heavy-Duty Winch, is primarily characterized by its slow operating speed, high traction capacity, compact structure, and stable and reliable operation. It typically employs an enclosed gear reduction box transmission and an electromagnetic brake (or hydraulic brake), ensuring excellent transmission efficiency, dust and water resistance, and reliable braking capability (automatic braking upon power failure), making it suitable for heavy-duty, low-speed precision operation scenarios.

The JM type electric winch is widely used in civil construction and installation engineering by construction installation companies, mining areas, and factories. It is particularly suitable for the installation and disassembly of large and extra-large steel structures and mechanical equipment, road and bridge engineering (such as bridge, port, and dock construction), as well as equipment installation in large factories and mines. Due to its safe and reliable lifting performance and orderly wire rope arrangement, it serves as crucial equipment for major component hoisting and precision positioning operations.

Features of JM type electric winch:

1.Slow Speed and High Traction Capacity: The JM type electric winch features a low rated speed. This slow-speed characteristic ensures smoother operation and facilitates precise position control, making it particularly suitable for the precision installation and positioning of large equipment and components. Simultaneously, it delivers powerful traction capacity, enabling it to handle the lifting and pulling tasks of heavy-weight loads.

2.Compact Structure and Reliable Load-Bearing Capacity: The JM type electric winch typically employs an enclosed gear reduction box for transmission, resulting in a compact structure and high transmission efficiency. Its orderly arranged wire rope contributes to safe and reliable lifting operations.

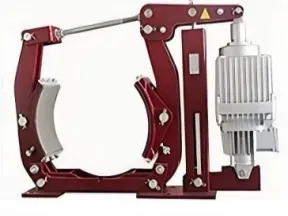

3.Safety Braking Device: Safety is the top priority for lifting equipment. The JM type electric winch commonly utilizes electromagnetic brakes (such as energy-efficient electromagnetic brakes) or hydraulic brakes. These brakes are normally closed, meaning they automatically engage in a power-off state to prevent load falling, ensuring high safety and reliability.

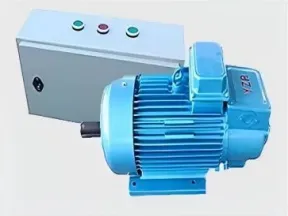

4.Power and Drive: The JM type electric winch is powered by an electric motor. For applications involving heavy loads and frequent starts, many models employ specialized hoisting motors (such as YZR series wound rotor asynchronous motors). These motors provide high starting torque, making them well-suited for heavy-load starting and frequent operation requirements.

5.Application Flexibility: Although the JM type electric winch itself has a compact structure, it can be combined with other equipment (for example, serving as the hoisting mechanism of a crane) or equipped with a frequency converter for speed control to adapt to more complex operational needs.

Application Scenarios of JM type electric winch:

1.Large-scale equipment installation and dismantling: This is the core application field of the JM type electric winch. Whether for mechanical equipment in large factory buildings, massive components of power energy projects (such as generator stators and rotors), or heavy reaction towers and tanks in the metallurgical and chemical industries, the JM series (particularly large-tonnage models) winches are frequently required for their hoisting, transportation, positioning, and subsequent dismantling and maintenance.

2.Bridge engineering construction: In the construction of highway and railway bridges, the JM type electric winch is used for hoisting and splicing bridge components, lifting systems of bridge erection machines, and various traction and tensioning operations. Its stable slow-speed characteristic is crucial for precision alignment.

3.Port terminals and water conservancy projects: At port terminals, it can be used for handling heavy cargo and equipment installation. In water conservancy and hydropower projects, it can be applied to gate installation, maintenance, and the construction of other heavy structures.

4.Mining operations and heavy-duty transportation: JM type electric winches are also found in mining tunnel operations and equipment installation. Furthermore, they play a significant role in any scenario requiring horizontal movement or dragging of heavy materials.

-

Drum: Diameter ≥19× wire rope diameter. Drum wall withstands rope winding tension; sides resist lateral forces. Distance from side plate edge to outermost rope ≥2× wire rope diameter.

Drum: Diameter ≥19× wire rope diameter. Drum wall withstands rope winding tension; sides resist lateral forces. Distance from side plate edge to outermost rope ≥2× wire rope diameter. -

Reducer: Consists of transmission parts, shaft, bearing, box & accessories. Functions to match speed & transmit torque between motor and working machine/actuator.

Reducer: Consists of transmission parts, shaft, bearing, box & accessories. Functions to match speed & transmit torque between motor and working machine/actuator. -

Motor & Control Box: Motor duty/rating complies with GB/755. Electrical components (motor, button, switch) ≥ IP44 (GB4942.1/4942.2). Locked cabinet-housed, securely installed; meets GB50150.

Motor & Control Box: Motor duty/rating complies with GB/755. Electrical components (motor, button, switch) ≥ IP44 (GB4942.1/4942.2). Locked cabinet-housed, securely installed; meets GB50150. -

Brake: Brake wheel uses ZG270-500 (φ<300mm uses HT200). Full separation when clutch is relaxed. Mounted between motor & reducer; wall resists rope tension, sides resist lateral forces.

Brake: Brake wheel uses ZG270-500 (φ<300mm uses HT200). Full separation when clutch is relaxed. Mounted between motor & reducer; wall resists rope tension, sides resist lateral forces. -

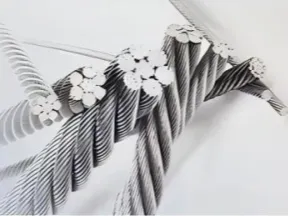

Wire Rope: Complies with GB/8918. Safety factor >5; minimum 3 safety laps on drum. With 2 laps remaining, withstands 125% rated load.

Wire Rope: Complies with GB/8918. Safety factor >5; minimum 3 safety laps on drum. With 2 laps remaining, withstands 125% rated load.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling