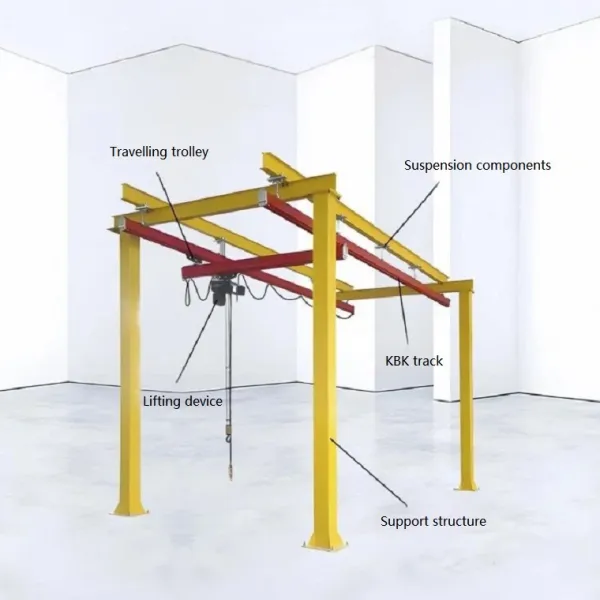

The KBK light-duty crane originated in Germany and is a modular crane system. This type of crane consists of a series of standardized components, including tracks, suspension systems, pulleys, electric hoists, etc.

KBK light cranes are divided into flexible KBK cranes, rigid KBK cranes, and aluminum alloy KBK cranes. They have changed the traditional industrial understanding of cranes, making crane design lighter, assembly more convenient, and use more ergonomic. It has revolutionized work efficiency and provided a more cost-effective option for the industrial sector. KBK light-duty cranes are widely used in various industrial scenarios, especially in light material handling and lifting equipment such as production lines, assembly lines, and conveyor lines.

1. Modular design: The various components of KBK lightweight crane are standardized and can be flexibly combined and configured according to actual needs. There are mainly three types of tracks: flexible, rigid, and aluminum alloy. They have light weight and high strength. By connecting them to the factory structure through hanging devices, the overall weight of the crane is greatly reduced, making it more lightweight and flexible.

2. Efficient and energy-saving: Advanced energy-saving technologies such as variable frequency speed regulation are adopted to effectively reduce energy consumption. Its efficient transmission system and optimized structural design enable the crane to quickly and accurately complete material handling tasks during operation

3. Easy to operate: The interface layout is reasonable, the control method is user-friendly, and ordinary workers can operate it after simple training. In addition, the design of the joystick conforms to ergonomic principles, reducing operator fatigue.

4. High precision control: With precise control functions, it can ensure the accuracy and stability of material handling.

5. Safe and reliable: During the design and manufacturing process, relevant safety standards are strictly followed, and various safety protection measures are adopted, such as overload protection, limit protection, brakes, etc., to ensure the stable operation and safe operation of the crane.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling