The MHB Type Single Girder Semi-Gantry Crane adopts a unique semi-gantry structure (with one leg operating on ground rails and the other leg-free side running directly on workshop rails), featuring compact design, small footprint, and flexible installation. Utilizing an electric hoist as the lifting mechanism, it covers a lifting capacity range of 1-20 tons with a typical working class of A3-A5. It supports multiple operation modes including floor remote control, pendant control, and cabin operation, and can operate stably in ambient temperatures from -25℃ to +40℃.

The MHB Type Single Girder Semi-Gantry Crane is mainly suitable for material loading, unloading and handling operations in machinery manufacturing workshops, assembly workshops, open storage yards and freight yards. Particularly ideal for space-constrained environments (such as workshops without column support) or situations requiring utilization of existing workshop structures as an alternative to traditional gantry or overhead cranes, it serves as an economical and efficient light-duty material handling solution. However, it should be noted that this crane is not suitable for flammable, explosive or corrosive environments, and must not be used for lifting molten metals, toxic or flammable substances.

Main Advantages of Single Girder Semi-Gantry Cranes:

Strong Site Adaptability: Can flexibly adapt to sites with height differences based on the civil engineering requirements of the location. Particularly suitable for areas like workshop sides or warehouse entrances where a building structure exists on one side.

High Cost-Effectiveness: The single girder structure and semi-gantry design typically result in lower manufacturing costs, installation costs (saving one ground track and its foundation), and later maintenance expenses compared to full gantry or double girder cranes.

Unique Space Utilization: Can fully utilize the internal space of buildings, achieve seamless indoor-to-outdoor operation, and obtain a broader working space.

Limitations to Consider:

Relatively Lower Stiffness: Compared to double girder gantry cranes, the overall stiffness of the single girder structure is lower. Consequently, the lifting capacity and span are usually limited to Q ≤ 20t and S ≤ 20m.

Selective Load Passage: If using L-shaped legs, the space for the load to pass through the leg area is relatively smaller; C-shaped legs can provide greater passage space.

Dependence on External Support: The leg-less side relies on the load-bearing beam of the workshop or trestle for support. It is essential to ensure this structure has sufficient strength and stability.

Application Scenarios of Single Girder Semi-Gantry Cranes:

Workshops and Warehouses: Widely used in areas against workshop walls or at warehouse entrances for material loading, unloading, and handling. Can be used in conjunction with overhead bridge cranes to improve overall workshop efficiency.

Open Storage Yards and Lines: Suitable for open storage yards or along railway and port lines for general loading, unloading, and lifting handling operations.

Logistics Transit and Container Handling: Used in warehouses, yards, and other places for indoor container lifting, outdoor stacking, or indoor-outdoor transfer operations.

-

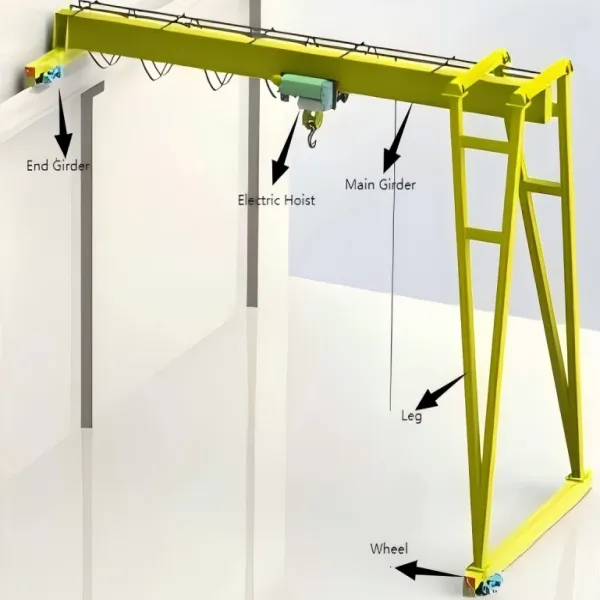

Main Girder: The main girder is the primary load-bearing structure of the crane, typically constructed as a box girder or truss structure using high-strength steel.

Main Girder: The main girder is the primary load-bearing structure of the crane, typically constructed as a box girder or truss structure using high-strength steel. -

Electric Hoist: The electric hoist provides dual-speed or variable frequency drive (VFD) control for precise load positioning.

Electric Hoist: The electric hoist provides dual-speed or variable frequency drive (VFD) control for precise load positioning. -

Leg: The MHB Type Semi-gantry Crane features a single-side leg (commonly box-section or H-section steel) on one end, while the other end moves along an elevated rail.

Leg: The MHB Type Semi-gantry Crane features a single-side leg (commonly box-section or H-section steel) on one end, while the other end moves along an elevated rail. -

Wheels: The wheels are forged from alloy steel and undergo heat treatment to enhance wear resistance.

Wheels: The wheels are forged from alloy steel and undergo heat treatment to enhance wear resistance. -

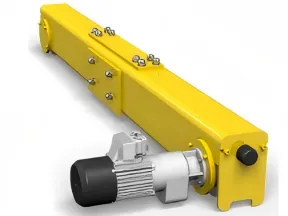

End Carriage: The end carriage connects the main girder to the traveling wheels and is equipped with driving mechanisms such as motors and gear reducers.

End Carriage: The end carriage connects the main girder to the traveling wheels and is equipped with driving mechanisms such as motors and gear reducers.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling