The MZ type grab bucket gantry crane is a lifting equipment commonly used for handling bulk materials in large outdoor sites. It is particularly suitable for processing blocky or irregular materials such as coal, ore, and sand/gravel.

It consists of several components including the main girder (which can be single or double girder structure), legs, end carriages, travel mechanism, hoisting and opening/closing mechanisms, grab, electrical system, and safety protection devices. These components work in coordination to achieve highly efficient mechanized handling of bulk cargo.

When selecting this type of equipment, it is necessary to specify key parameters such as lifting capacity, span, and lifting height, as well as details like the power supply method for the gantry travel (safety conductor rails or cable reel), and the position and door opening direction of the operator's cab.

Features of MZ Type Grab Bucket Gantry Cranes

High Operational Efficiency

Achieves continuous operation of bulk materials through "grasping, lifting, moving, and unloading".

Integrated Functions

A single unit integrates three major functions: loading/unloading, transportation, and stacking.

High Space Utilization

The space under the gantry can be fully utilized for material stacking or vehicle passage, enabling three-dimensional space utilization. This is particularly suitable for cramped sites or expensive port and terminal areas.

Wide Adaptability

By replacing with different types of grabs (such as two-jaw grabs for coal and sand/gravel, multi-tine grabs for large-sized ores, timber grabs for logs, etc.), it can handle various types of bulk cargo and some long-length goods.

Flexible Operation

Operation can be selected from either the operator's cabin or via remote control.

Robust, Durable, and Easy Maintenance

The box-type double girder structure offers great rigidity and strength, enabling it to withstand frequent and heavy-duty operations.

Major mechanisms (such as hoisting and opening/closing) feature a high degree of modularization, facilitating inspection and maintenance.

Applications of MZ Type Grab Bucket Gantry Cranes

Ports and Inland Waterway Terminals

Used for loading and unloading bulk commodities like coal, ore, grain, and fertilizer. It serves as the primary handling equipment in bulk cargo terminals.

Thermal Power Plants

Used in the plant's coal storage yard for stacking and reclaiming coal, feeding the coal handling system for the boilers.

Metallurgical and Steel Plants

Handles the unloading, storage, and transfer of raw production materials like iron ore, limestone, and coke in the raw material yard.

Building Materials and Construction Engineering

Sand and Aggregate Yards: For handling, loading/unloading, and storing building materials like sand and crushed stone.

Large-scale Water Conservancy, Hydropower, Highway, and Bridge Construction Sites: Processes sand and aggregate near concrete batching plants.

Railway Freight Yards and Logistics Centers

Specifically used for the rapid loading and unloading of bulk materials from railway gondola cars (e.g., coal cars, ore cars).

Other Industrial Fields

Can be found anywhere involving large-scale bulk material handling, such as wood chip yards in pulp mills and fuel storage yards in waste-to-energy plants.

-

Main Girder: Core load-bearing component of the bridge, box-type single/double girder.Spans two legs, provides trolley travel runway.Strength/rigidity determine overall stability & lifting capacity.

Main Girder: Core load-bearing component of the bridge, box-type single/double girder.Spans two legs, provides trolley travel runway.Strength/rigidity determine overall stability & lifting capacity. -

Travel Mechanism: Gantry Travel (crane longitudinal track movement) & Trolley Travel (grab-equipped trolley transverse main girder movement).Combination enables arbitrary grab positioning within track area.

Travel Mechanism: Gantry Travel (crane longitudinal track movement) & Trolley Travel (grab-equipped trolley transverse main girder movement).Combination enables arbitrary grab positioning within track area. -

Crane TrolleyTwo independent winch systems (hoisting/opening-closing drums) + wire ropes.Coordinated/alternating control enables grab descent, grabbing, hoisting & unloading.

Crane TrolleyTwo independent winch systems (hoisting/opening-closing drums) + wire ropes.Coordinated/alternating control enables grab descent, grabbing, hoisting & unloading. -

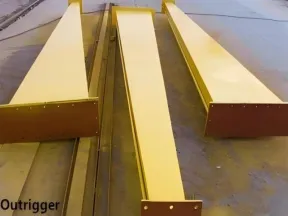

Outrigger The columns that support the main girder and connect to the end carriages. Classified by structure into L-type and C-type, they effectively accommodate track irregularities and prevent structural binding.

Outrigger The columns that support the main girder and connect to the end carriages. Classified by structure into L-type and C-type, they effectively accommodate track irregularities and prevent structural binding. -

Grab Bucket: Used for handling bulk materials. Its jaws open and close via wire rope or hydraulic actuation, and it can be exchanged according to the characteristics of the material being handled.

Grab Bucket: Used for handling bulk materials. Its jaws open and close via wire rope or hydraulic actuation, and it can be exchanged according to the characteristics of the material being handled. -

Operator's Cab: Typically suspended under the main girder, it houses the control levers and instruments.

Operator's Cab: Typically suspended under the main girder, it houses the control levers and instruments.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling